Computer-controlled High-speed Bartacking Sewing System

Price 236600 INR/ Piece

Computer-controlled High-speed Bartacking Sewing System Specification

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Color

- White

- Warranty

- 1 Year

Computer-controlled High-speed Bartacking Sewing System Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Main Domestic Market

- Andhra Pradesh

About Computer-controlled High-speed Bartacking Sewing System

This Computer-controlled High-speed Bartacking Sewing System is used in the preparation of garments, wherein more strength is required for supporting the extra load. Therefore, it is used in the making of a pocket corner, belt loop and at the end of the zipper. It is also an excellent alternative for hand sewing and thus is always high on demand. Moreover, some of its integral parts are throat plate, needle, pressure lever, back stitch lever, thread guide, and bobbin case. Computer-controlled High-speed Bartacking Sewing System consists of 18 to 72 stitches, wherein user is also allowed to change the stitch density.

Computer-controlled, High-speed Bartacking Sewing System

LK-1900BN-HS

LK-1900BN-WS (with large hook for heavy-weight materials)

The machine achieves sewing speed of 3,200sti/min. The machine's starting, stopping, thread-trimming and automatic presser lifting speeds have been increased to significantly shorten total cycle time. The needle's penetrating force into the material has been increased. This provides an improved responsiveness to heavy-weight materials for the H type machine. The W type has adopted a large shuttle hook, which reduces the frequency of bobbin-thread changing to enable highly efficient sewing work.

| Model name | LK-1900BN-HS | LK-1900BN-WS |

| Application | Heavy-weight | With large hook for heavy-weight |

| Max. sewing speed | 3,200sti/min | 2,700sti/min |

| Sewing area | 30mm (L)40mm (W) | |

| Max. stitch length | 0.1mm10mm (0.1step) | |

| Lift of the work clamp foot | Standard 14mm (17mm when the reverse-rotation needle-up function) | |

| Needle | DP-17 (#21) | |

| Number of standard patterns |

51 patterns | |

| Number of data that can be input |

200 patterns (for up to 150 patterns, sewing data can be added) |

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Sewing Machine Category

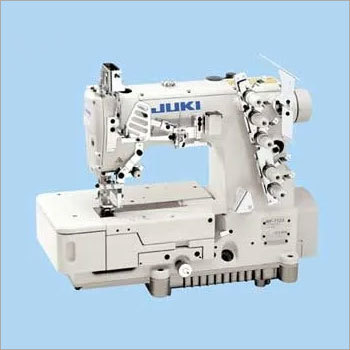

Coverstitch Machine

Price 130000 INR / Number

Minimum Order Quantity : 10

Computerized : No

Control System : Other, Manual

Automatic Grade : SemiAutomatic

Type : Coverstitch Machine

Juki Industrial Sewing Machine

Price 46700 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Control System : Frequency Speed Control

Automatic Grade : SemiAutomatic

Type : Sewing Machine

Zigzag Stitching Machine

Price 543600 INR / Unit

Minimum Order Quantity : 1 Piece

Computerized : Yes

Control System : PLC Control

Automatic Grade : Automatic

Type : sewing machine

Sewing Machine

Price 993000 INR / Number

Minimum Order Quantity : 10

Computerized : Yes

Control System : Frequency Speed Control

Automatic Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS