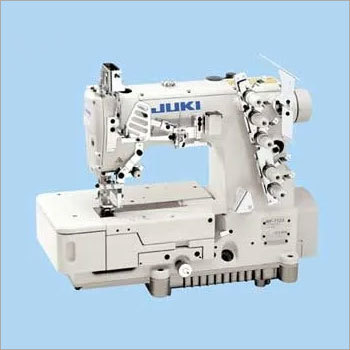

Coverstitch Machine

Price 130000 INR/ Number

Coverstitch Machine Specification

- Type

- Coverstitch Machine

- Material

- Metal and High-Grade Plastic

- Capacity

- High Speed, Suitable for Light and Heavy Fabrics

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Knitting Method

- Coverstitch

- Knitting Style

- Flatbed

- Voltage

- 220V

- Weight

- Approx. 12 kg

- Color

- White & Grey

- Dimension (L*W*H)

- 430 mm x 280 mm x 330 mm

About Coverstitch Machine

Advanced Stitching Capabilities

This coverstitch machine supports double and triple needle configurations, allowing for versatile stitching options on both light and heavy knit fabrics. With a maximum stitch width of 6 mm and length of 4.5 mm, you can achieve professional seams, hems, and decorative finishes. The flatbed design ensures smooth fabric handling throughout every project.

Efficient and User-Friendly Operation

Featuring a clutch motor and variable pedal speed, this machine operates efficiently and quietly. The automatic lubrication system minimizes maintenance while ensuring optimal performance. Its semi-automatic controls, accessible presser foot lift, and manual adjustments make it ideal for users seeking control and convenience in their workflow.

Robust and Reliable Construction

Built from a combination of metal and high-grade plastic, this coverstitch machine is engineered for durability and high-speed production. Designed for industrial and commercial use in India, it comes as a comprehensive packageincluding machine head, stand, motor, and an accessories kitsuitable for service providers, suppliers, traders, and wholesalers.

FAQs of Coverstitch Machine:

Q: How do I adjust the stitch width and length on this coverstitch machine?

A: You can easily set the stitch width (up to 6 mm) and length (up to 4.5 mm) using the adjustment dials located on the machines main body. This gives you precise control for various types of stitching applications on different fabric weights.Q: What types of fabrics are best suited for this machine?

A: This coverstitch machine efficiently handles a wide range of jersey and knit fabrics, from lightweight to heavyweight materials, ensuring seam durability and professional finishes regardless of fabric type.Q: When should I use double versus triple needle settings?

A: Double needle settings are ideal for standard seams and hems, while the triple needle configuration is perfect for reinforced seams or decorative topstitching, offering added strength and visual appeal.Q: Where can the machine be utilized in terms of industry or workspace?

A: Designed for flexibility, this machine is suitable for tailoring shops, garment manufacturers, and textile workshops, especially those specializing in knitwear and jersey production across India.Q: What is the process for switching between 2, 3, or 4-thread stitching?

A: To change between 2, 3, or 4-thread configurations, simply follow the threading guide included in the accessories kit to adjust the threading path and needles according to your selected coverstitch type.Q: How does the automatic lubrication system benefit ongoing machine use?

A: The automatic lubrication system ensures consistent oil distribution, reducing friction and wear on moving parts, which translates to longer machine life and minimal maintenance requirements.Q: What are the main benefits of choosing this coverstitch machine model?

A: This machine offers reliable, high-speed performance with low noise. Its variable speed control, robust construction, and versatile application capabilities make it a smart investment for both small-scale and industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Sewing Machine Category

Chainstitch Machine

Price 360600 INR / Number

Minimum Order Quantity : 10

Automatic Grade : SemiAutomatic

Computerized : No

Control System : Other, Manual

Type : Chainstitch Machine

Overlock / Safety Stitch Machine

Price 58000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Automatic Grade : Automatic

Computerized : Yes

Control System : PLC Control

Type : sewing machine

jack f4 DIRECT DRIVE SINGLE NEEDLE

Price 22500 INR / Piece

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Control System : Frequency Speed Control

Type : sewing machine

Direct Drive, High Speed, 1 Needle, Needle Feed, Lockstitch Machine with Automatic Thread Trimmer

Price 260000 INR / Number

Minimum Order Quantity : 5

Automatic Grade : Automatic

Computerized : Yes

Control System : Frequency Speed Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS